Terminology

Useful Technical Terminology

Adhesive for paper and carton boxes (sealed type)

The substance used for the gluing of paper to form the paper board in Corrugator, is based on the starch. For the formation of the carton boxes (side tab gluing), a chemical glue (PVA) is used.

Basis weight

Basis weight is the weight of the paper or board per unit area.

Units: g/m2 paper or paperboard.

Board

A general term for various types of sheets glued together corrugated or not.

Burst strength test of paper and board (Mullen Test / BST-Burst Strength Test)

This method refers to a laboratory test for determining the paper or paperboard resistance to internal and external pressure through the expansion of a membrane, which swells under the glycerin pressure until complete rupture of the specimen occurs. The strength of the paper burst determines the energy of the bond of the fibers, constituting the sheet of paper. The greater the amount of energy is, the greater the measurement of the test. As far as the corrugated board, this measurement is influenced mainly by the respective strength of the liners and indicates the strength of the paperboard to shocks, which mainly exist in the use and transfer of carton boxes.

Units: ΚPa

Composite (mix) paperboard

Corrugated paperboard composed from fully recycled paper as well as from virgin paper.

Corrugator

Machine that produces corrugated paperboard.

Corrugated box strength under vertical compression (BCT-Box Compression Test)

This method refers to a laboratory test for the determination of empty formed carton box strength, when a vertical compression is applied. This is the most important test for the final packaging, since it gives the measure of the box stackability. It is directly related to the resistance raised by the carton during the stacking on a pallet, due to the vertical load from the weight of the upper rows of filled boxes. The stress accumulation to a carton box due to the stacking load is distributed evenly around its perimeter. By increasing the load, the box corners take most of it up to a critical value in which the long sides of the box are bent outwards or inwards. Next, failure occurs in the corner regions, followed by the collapse of the container. For this reason it is essential to properly arrange of cardboard boxes on pallets, so that the box corners have stable backgrounds.

Units: Κgf of box

Corrugation flutes profile properties

There are 3 main fluting types E, B, C and their combinations EB, BC.

Their properties are as such:

[Ε] Fluting: Paperboard consisting of three layers, two liners and one corrugated. Nominal thickness : 1,6 mm. Printing performance : Very Good. Stacking strength : Poor

[Β] Fluting: Paperboard consisting of three layers, two liners and one corrugated. Nominal thickness : 2,8 mm. Printing performance : Fair. Stacking strength : Good

[C] Fluting: Paperboard consisting of three layers, two liners and one corrugated. Nominal thickness : 3,8 mm. Printing performance : Poor. Stacking strength : Very Good

[EB] Fluting: Paperboard consisting of five layers, three liners and two corrugated in Ε & Β fluting respectively. Nominal thickness : 4,2 mm. Printing performance : Very Good. Stacking strength : Very Good

[BC] Fluting: Paperboard consisting of five layers, three liners and two corrugated in B & C fluting respectively. Nominal thickness : 6,5 mm. Printing performance : Fair. Stacking strength : Excellent

Corrugated paper board cross-section strength (ECT-Edge Crush Test)

This method refers to a laboratory test for determining the strength of the paperboard cross-section, when a force is applied in parallel to the direction of the flutes. This property is very important, since it indicates the resistance that a shaped box shows during stacking, as it is able, with some mathematical transformations, to determine with reasonable accuracy the carton box strength during palletizing.

Units: ΚΝ/m of paperboard

Die Cutting unit

Die cutting unit is a wooden matrix on which stainless steel cutting, piercing and creasing blades as well as polymerized and special rubbers are placed. The blades cut, pierce and crease the corrugated board in parallel and perpendicularly to the axis of the flutes, while the rubbers detach and promote it. The die cutting unit is used to produce a packaging material of specific requirements.

Fibers

The production of the papers, used as raw material for the corrugated paperboard production, is achieved either by virgin trees cellulose fibers, or reusable fibers via paper recycling. The wood fibers are tissues of long and thick-walled cells, which firstly form the skeletal substance of the tree and secondly create the pipelines transferring useful nutrients for its life. If these cells are separated from each other, thin and long fibers result. The adhesive between these cells is called lignin, while the main structural component is a polysaccharide called cellulose. The destruction of the lignin layer is achieved chemically or mechanically using a relatively high temperature and the outcome of this process is the virgin pulp of cellulose fibers.

Liner

Liner refers to the inner or outer paper layer in a corrugated board.

Pantone colors

Pantone colors are a set of standard shades that have been created to help designers, printers and their customers to have an idea of which colors are to be printed. In most design applications, PANTONE colors are known as Spot Colors. For colors choosing, there are special specimens, with a huge range of shades. Each color corresponds to a particular code.

Paperboard Warp

The paperboard warp is defined as the deviation from flatness.

Paper grades

Packaging papers are divided into two categories, virgin and recycled, depending on the pulp composition and content, which are produced from, of trees cellulose fibers.

Virgin papers:

Kraft liner: This paper, which is used as a liner when corrugated paperboard is produced, comes from soft trees (pine, spruce, etc.) raw cellulose fiber pulp and has the strongest mechanical characteristics (white or brown).

Semichemical: A general term for papers to be fluted. They are produced from wood pulp cellulose fibers from rather hard trees such as oak, birch, etc.

Recycled papers:

Test Liner: Produced by the reuse, with appropriate treatment methods, of paperboard boxes and other types of paper scraps, in combination with various additives (white or brown).

Medium: Produced by the reuse, with appropriate treatment methods, of cardboard boxes and other types of paper scraps, in combination with various additives (brown).

Printing cliché

In older times, rubber was the raw material for the production of flexographic clichés. Today, this is replaced by a photopolymer material in solid or liquid form. The molecular structure of the polymeric materials alters after their exposure to ultraviolet radiation (UV), leading them to harden. This property of them is the basis for building flexible printing plates. The choice of materials used for manufacturing the clichés, depending on the type of ink and the type of material to be printed. For making photopolymer clichés, either photopolymer sheets or liquid photopolymer are used. The clichés manufacturing process, in general, is the same.

Resistance of paper to air passage (Gurley Method)

Gurley method refers to a laboratory test for determining the time needed, so that a specific air quantity may pass through a certain paper surface.

Units: sec

Resistance of paper to water passage (COBB method)

Cobb method refers to a laboratory test for determining the resistance of the paper to water passage. The COBB test expresses the amount of water absorbed from one side of the paper, at a given time. All types of paper are required to be able to absorb a specific amount of water in the form of adhesive or ink, but without the latter exceeding a threshold, and without altering their mechanical properties.

Units: g/m2 of paper

Strength of paper flutes under a vertical compression load (CCT-Corrugated Crush Test)

This method is a laboratory paper strength test, according to which the paper after been corrugated, undergoes a vertical stress (load parallel to the flutes and therefore perpendicular to the axis of the fibers forming the paper). The process simulates the load received by the corrugated paper, inside the carton wall, when the box is placed on the pallet, right after the products are packed inside the container.

Units: ΚΝ/m of paper

Strength of paper in annular form (RCT-Ring Crush Test)

This method refers to a laboratory test for determining the level of the paper strength, having a ring shape, when a vertical load is applied perpendicularly to the fibers axis. It expresses how well the fibers forming the paper are tied up together, thus giving information about their flexibility or stiffness during buckling.

Units: ΚΝ/m of paper

Strength & Stiffness of paper flutes (CMT-Concora Medium Test)

This test is a laboratory one for determining the strength-stiffness of the paper flutes, which after the corrugation are glued on a strip of paper, so that they cannot move. In this way, when a vertical compressive force is applied perpendicularly to the corrugation plane, the flute tips resist giving a measure of their stiffness. The rigidity of the flute is an important quality parameter, because it indicates the ease or difficulty raised by the corrugated paper, in order to maintain at a constant distance both liners. The criticality of this parameter is that if the corrugated paper fails in its mission, then distortion and buckling phenomena of cardboard appear, which ultimately lead to destabilization and collapse of the package in general. Units: Newton

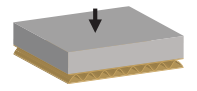

Strength & Stiffness of paper flutes in the paperboard (FCT-Flat Crush Test)

This method refers to a laboratory test for determining the strength of the paperboard flutes, when vertical compressive load is applied, perpendicular to the plane of corrugation. The rigidity of the flute is an important quality parameter, because it indicates the ease or difficulty raised by the corrugated paper, in order to maintain at a constant distance both liners. The criticality of this parameter is that if the corrugated paper fails in its mission, then distortion and buckling phenomena of paperboard appear, which ultimately lead to destabilization and collapse of the package in general.

Units: KPa

Tensile paper strength test (MD, CD)

This test is a laboratory one for determining the paper tensile strength. This method measures the tensile strength of the paper either in the longitudinal axis of the paper machine (MD-Machine Direction), which is identical to the fiber orientation or in the direction perpendicular to the machine (CD-Cross Direction). The tensile strength of the paper is the resistance presented by the paper during bending. This paper bending may happen when boxes are stacked together on a pallet and buckling phenomena of their walls occur. Also, the tensile paper strength may be shown through the easiness or difficulty of forming the corrugated fluted paper.

Units: ΚΝ/m of paper

Thickness of Paper or Paperboard

The thickness of the paper is determined mainly by its weight, while the paperboard thickness is specified by the type of fluting.

Units: μm of paper / mm of paperboard